In the realm of fabrics, there exists one that reigns supreme in terms of elegance,…

Say Goodbye to Single Use Plastics with Bottle-to-Bottle Recycling

The Innovation

It all started with a simple word – recycling, which isn’t so simple now. Recycling is now evolving into a complex process and with each development, we are introducing a new way to save the planet. The packaging of the products is also being made from recycled material now. It is estimated that companies are trying to use at least 25% recycled material in their product packaging by 2025.

Bottle-to-bottle recycling is a process that stays true to its name. When the companies want to reuse their bottle packaging (mineral water bottles, soda bottles, etc) cannot simply gather these plastic bottles from the trash and reuse them after a wash. These bottles need to be processed and remade. Even thorough washing isn’t enough. They have to be broken down and manufactured again to be reused.

The process of Bottle-to-Bottle Recycling

It all begins with collecting bottles from various areas filled with trash. The cleanliness of the city or town is also strongly promoted by these processes as it utilizes waste as a raw material. In this stage, the bottles are cut open to be washed and sterilized. The glue and labels of the bottles are neatly stripped off.

A sorting process also takes place where non-PET materials that cannot be recycled are removed from the lot before proceeding. It is done with the use of a machine that eliminates any wood or bulky waste. Colored plastic bottles are also sorted out leaving behind only the transparent ones.

After sorting comes the grinding. This is the process of converting the plastic to clear flakes. The shredding at this stage also makes sure that all the contaminants are removed. Any leftover pieces of metals, PVC from labels, etc are removed using caustic soda mixed in hot water and further with cold water. This treatment will fully decontaminate the materials.

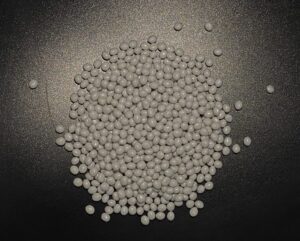

Once the PET flakes are ready, they are heated to melt and remolded into long strings in a machine known as an extruder. At the end of this, the strings are cut into smaller granules or pellets.

Application

These pellets can be sold to manufacturers or the company manufacturing the final product can have this entire recycling plant as well. The pellets are now ready to be used for making an entirely new product.

These pellets are then put into molds to make a miniature version (known as a pre-form) of the new product. This mini mold is then blown into with heat and high air pressure. Finally, it becomes a full-sized product made from recycled materials. This is known as blow molding.

Further, this application can be divided into two parts – cold fill bottles and hot fill/heat set bottles.

Cold-fill bottles are the ones used for packing cold beverages like chilled summer juices, cold coffee, cold drinking water, etc. These bottles are thoroughly sterilized and they are meant to be durable.

As we see in this advertisement from Coca-Cola’s official website, each company is making its contribution towards a sustainable future. Bottle-to-bottle recycling plays a vital role in this initiative.

Heat-set bottles require higher thermal capacity. The bottles are sterilized when they come in contact with the hot substance. Blow molding that we discussed above is observed for heat set bottles as using this process constrains the thermal deformation of the bottles.

There are many more applications for these pellets.

Sustainability

At Anil International, we strongly believe in working towards a greener future and thus, support products that help us take a step closer to this idea. We trade in PET chips and recycled fabrics like recycled cotton and polyester.

We source from certified suppliers who give assured quality products. Join us in using the fabrics that help the future.

Follow us on LinkedIn for more updates.